Product

-

EV High-Voltage Cable

-

EV Charging cable

UL charging cable

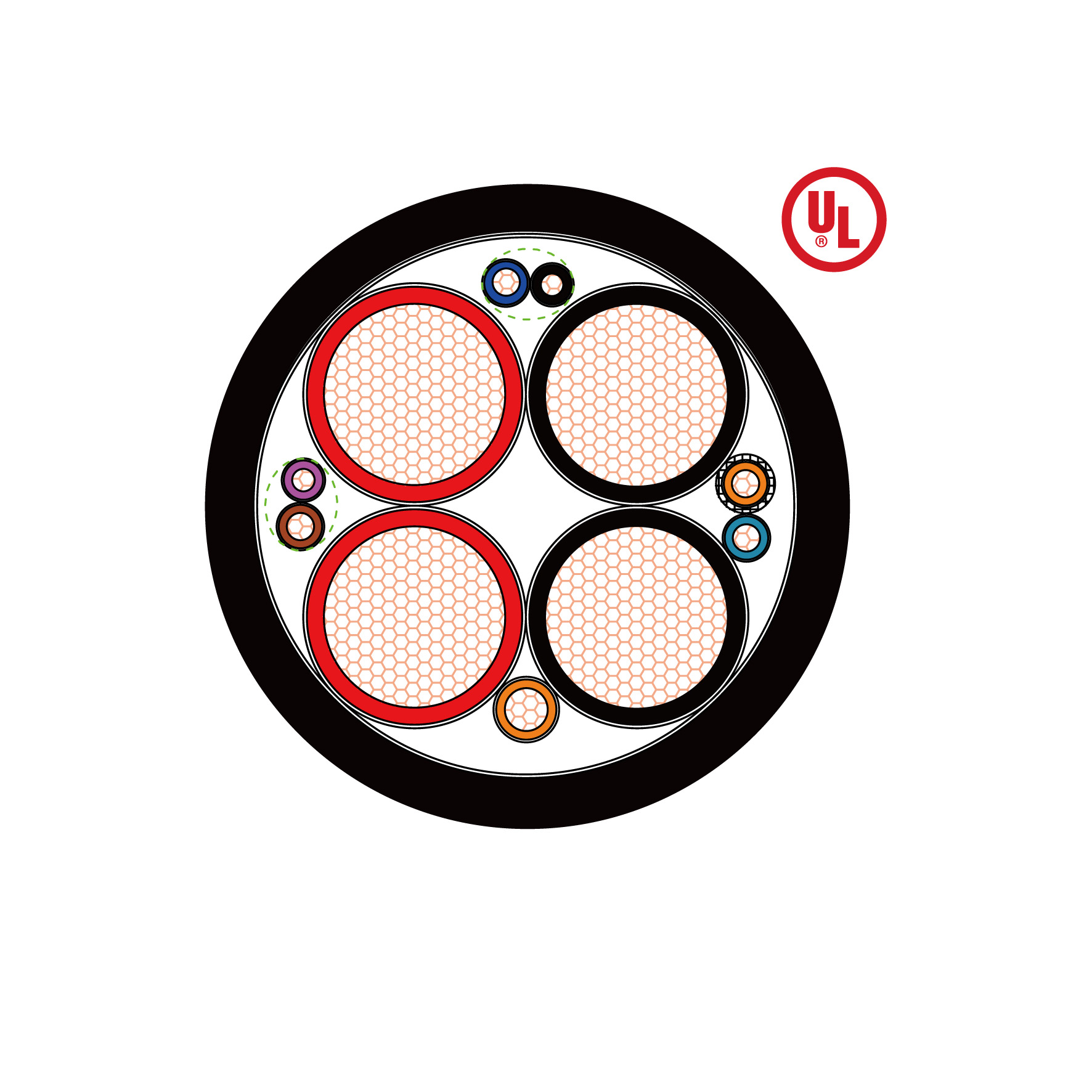

UL EV charging cable (Suitable for NACS、CCS1)

Reference Standard:UL 2263

UL No.:E345899

Construction |

Features |

1.Conductor |

Rated temperature:-50℃~105℃ |

Material: Bare Copper |

Rated Voltage:1000V |

2.Insulation |

Conductor Resistance(at 20°C):8AWG≤2.23Ω/km;10AWG≤3.51Ω/km;16AWG≤14.1Ω/km;Test method Comply with UL 2556 |

Material: TPE |

15°C Insulation Resistance:8AWG≥34Ω.m;10AWG≥34Ω.m;16AWG≥45Ω.m;Test method Comply with UL 2556 |

Color:Black,red,Green/Yellow or other |

Dielectric Voltage: 4.0kV AC/1min(8AWG),3.0KV AC/1min(10AWG), 2.0KV AC/1min(16AWG). No Breakdown. Test method Comply with UL 2556 |

3.Filler |

Bending Radius Min:≥6OD. |

Material: PP hemp or cotton yarn |

Hot Shock:150℃/1h No cracks Test method Comply with UL 2556 |

4.Tape |

Flame Test:FT1.Test method Comply with UL 2556 |

Material:Non-woven fabrics |

Insulation tensile strength:Before Aging 5.5Mpa;After Aging(136°C/168H)≥75%Original.Test method Comply with UL 2556 |

5.Sheath |

Insulation Elongation:Before Aging200%;After Aging(136°C/168H)≥75%Original.Test method Comply with UL 2556 |

Material: TPE |

Jacket tensile strength:Before Aging 8.3Mpa;After Aging(136°C/168H)≥75%Original.Test method Comply with UL 2556 |

Color: Black or Orange |

Jacket Elongation:Before Aging200%;After Aging(136°C/168H)≥75%Original.Test method Comply with UL 2556 |

|

Cold Bending Test:-40°C/4H,NO Cracking.Test method Comply with UL 2556 |

|

Hot Shock Test:150°C/1H,NO Cracking.Test method Comply with UL 2556 |

Type |

Main Lines Size & E |

Signal Lines Size |

Permissible ampacity@20°C ambient Ref. |

Over diameter Ref. mm |

OMG EVC 1001 |

10AGW/2+10AGW |

22AGW(20AGW/18AGW/16AGW)0-6 |

32A |

12.0±0.5 |

OMG EVC 1002 |

9AGW/2+10AGW |

40A |

13.8±0.5 |

|

OMG EVC 1003 |

8AGW/2+10AGW |

48A |

15.0±0.5 |

|

OMG EVC 1004 |

6AGW/2+8AGW |

80A |

18.9±0.5 |

|

OMG EVC 1005 |

3AGW/4+12AGW(14AGW/10AGW) |

18AGW(20AGW/22AGW)0-8 |

170A(200A) |

28.3±1.0 |

OMG EVC 1006 |

2AGW/4+12AGW(14AGW/10AGW) |

200A(250A) |

31.0±1.0 |

|

OMG EVC 1007 |

1/0AGW/4+12AGW(14AGW/10AGW) |

300A-350A |

36.5±1.0 |

|

OMG EVC 1008 |

4AGW/2+14AGW |

120A |

21.0±1.0 |

|

OMG EVC 1009 |

1AGW/4+14AGW |

|

250A(300A) |

34.0±1.0 |

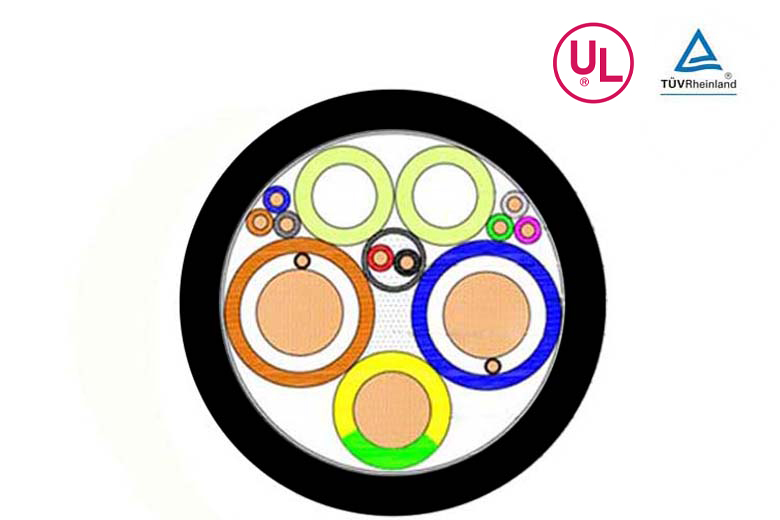

UL 2263 EV charging cable (Suitable for CCS1)

Reference Standard:UL 2263

UL No.:E345899

| Construction | Features |

| 1.Conductor | Rated temperature:-40℃~105℃ |

| Material: Bare Copper | Rated Voltage:300V;600V or 1000V |

| 2.Insulation | Flame Test: VW-1 Test method Comply with UL 2556 |

| Material: TPE | Min: Bending Radius: ≥6*OD |

| colour:Black,Red,Green/Yellow or other | Dielectric Voltage: 1.5kVac/1min. No Breakdown Test method Comply with UL 2556 |

| 3.Filler | Cold Bending:-40℃/4h No cracks Test method Comply with UL 2556 |

| Material: PP hemp or cotton yarn | Hot Shock:150℃/1h No cracks Test method Comply with UL 2556 |

| 4.Tape | Oil Resistance:IRM902, 60℃/168h Tensile and Elongation ≥70% Unaged value |

| Material:Non-woven fabrics | Crush Resistance:S≤12AWG 4.45kN, 12AWG<S≤2AWG, 11.1kN, 2AWG<S 15.6kN |

| 5.Sheath | Weather Resistance:720hin a xenon arc weatherometer, No cracks |

| Material: TPE | Environmental Requirements:Compliant with RoHS and REACH |

| Color: Black or Orange(customizable) |

| Type | Size | Conductor Stranded OD mm Ref. | Max. Conductor resistance mΩ/m@20℃ | Permissible ampacity@20℃ ambient Ref. | Over diameter Ref. mm | Packing M/Reel (Ref.) |

| 600V or 1000V EVE(TPE) | 3×16AWG | 1.5/1.2 | 14.1 | 12A | 10.8±0.5 | 1000m/700# |

| 3×14AWG | 1.9/1.2 | 8.88 | 16A | 11.8±0.5 | 800m/700# | |

| 3×12AWG | 2.4/1.2 | 5.58 | 23A | 14.3±0.5 | 500m/700# | |

| 3×10AWG | 3.0/1.2 | 3.51 | 32A | 15.6±0.5 | 500m/700# | |

| 2×8AWG+10AWG | 4.3/3.0 | 2.23/3.51 | 46A | 20.9±0.8 | 500m/950# | |

| 2×6AWG+8AWG | 5.4/4.3 | 1.40/2.23 | 63A | 23.4±0.8 | 400m/950# | |

| 3×16AWG+1×18AWG | 1.5/1.2 | 14.1/22.4 | 12A | 11.4±0.5 | 800m/700# | |

| 3×14AWG+1×18AWG | 1.9/1.2 | 8.88/22.4 | 16A | 13.5±0.5 | 500m/700# | |

| 3×12AWG+1×18AWG | 2.4/1.2 | 5.58/22.4 | 23A | 14.5±0.5 | 500m/700# | |

| 3×10AWG+1×18AWG | 3.0/1.2 | 3.51/22.4 | 32A | 15.8±0.6 | 500m/700# | |

| 2×8AWG+10AWG+18AWG | 4.3/3.0 | 2.23/3.51/22.4 | 46A | 20.9±0.8 | 500m/950# | |

| 2×6AWG+8AWG+18AWG | 5.4/4.3 | 1.40/2.23/22.4 | 63A | 23.4±0.8 | 400m/950# | |

| 2×4AWG+6AWG+18AWG | 6.6/5.4 | 0.882/1.4/22.4 | 75A | 27.0±0.9 | 300m/950# | |

| 3×16AWG+2×18AWG | 1.5/1.2 | 3.51/22.4 | 12A | 12.2±0.5 | 500m/700# | |

| 3×14AWG+2×18AWG | 1.9/1.2 | 8.88/22.4 | 16A | 14.1±0.5 | 500m/700# | |

| 3×12AWG+2×18AWG | 2.4/1.2 | 5.58/22.4 | 23A | 15.1±0.6 | 500m/700# | |

| 3×10AWG+2×18AWG | 3.0/1.2 | 3.51/22.4 | 32A | 15.8±0.6 | 500m/700# | |

| 2×8AWG+10AWG+2×18AWG | 4.3/3.0 | 2.23/3.51 | 46A | 20.9±0.8 | 500m/950# | |

| 2×6AWG+8AWG+2×18AWG | 5.4/4.3 | 1.40/2.23 | 63A | 23.4±0.8 | 400m/950# | |

| 2×4AWG+6AWG+2×18AWG | 6.6/5.4 | 0.882/1.4 | 75A | 27.0±0.9 | 300m/950# | |

| 2×2AWG+4AWG+2×18AWG | 8.2/6.6 | 0.555/0.882 | 100A | 30.5±1.0 | 400m/1200# | |

| 2×1/0AWG+2AWG+4×16AGW | 10.5/8.2 | 0.349/0.555 | 200A | 38.0±1.0 | 250m/1200# | |

2×3/0AWG+1/0AWG (2×3/0AWG+4AWG+6X18AWG)

3/0AWG Ground line minimum 4AWG

|

13.05/10.5 | 0.219/0.349 | 260A | 45.0±1.0 | 150m/1200# | |

| 4X1-0AWG+4AWG+6X18AWG | 10.4/6.5 | 0.351/0.882/23.6 | 300A/350A | 45.7±1.2 | 150m/1200# | |

| 300V EVJE(TPE) | 3×16AWG | 1.5/1.2 | 3.51/22.4 | 12A | 9.5±0.3 | 1200m/700# |

| 3×14AWG | 1.9/1.2 | 8.88/22.4 | 16A | 10.2±0.5 | 1000m/700# | |

| 3×12AWG | 2.4/1.2 | 5.58/22.4 | 23A | 11.4±0.5 | 800m/700# | |

| 3×16AWG+1×18AWG | 1.5/1.2 | 3.51/22.4 | 12A | 10.5±0.5 | 1000m/700# | |

| 3×14AWG+1×18AWG | 1.9/1.2 | 8.88/22.4 | 16A | 11.1±0.5 | 80m/700# | |

| 3×12AWG+1×18AWG | 2.4/1.2 | 5.58/22.4 | 23A | 12.2±0.5 | 500m/700# | |

| 3×16AWG+2×18AWG | 1.5/1.2 | 3.51/22.4 | 12A | 11.3±0.5 | 800m/700# | |

| 3×14AWG+2×18AWG | 1.9/1.2 | 8.88/22.4 | 16A | 12.0±0.5 | 800m/700# | |

| 3×12AWG+2×18AWG | 2.4/1.2 | 5.58/22.4 | 23A | 13.1±0.5 | 500m/700# | |

| The number of signal wires can be 0~6, or more, the signal wire conductor specifications can be 16AWG, 18AWG, 20AWG, 22AWG. | ||||||

The above product specifications, sizes, and structures may be changed due to technological progress. Similar specifications can be designed and manufactured according to customer needs.